2023 Construction Industry Trends to Watch Out For

Modular Design and Prefabrication

Fewer Workers

Green Building and Practices

Material Shortages and Price Uncertainties

More Technology

Smart Cities

Prepare for Success in 2023

*Image from Quang Nguyen Vinh on Pexels.com

It’s 2023, which means there are new building trends. Here’s what you need to know.

2022 was an interesting year for the construction industry. Between the rising costs and labor shortages, the construction industry had plenty of challenges. Still, client demand remained high.

However, 2023 is here, so it’s time to look at what’s coming through the pipeline in the year to come. After all, if you know which new construction industry trends are coming your way, you can prepare and even get ahead of the competition.

Top 6 Construction Industry Trends in 2023

Every year brings new surprises, and no one can truly predict the future. However, here are some trends you should keep an eye out for in the coming year:

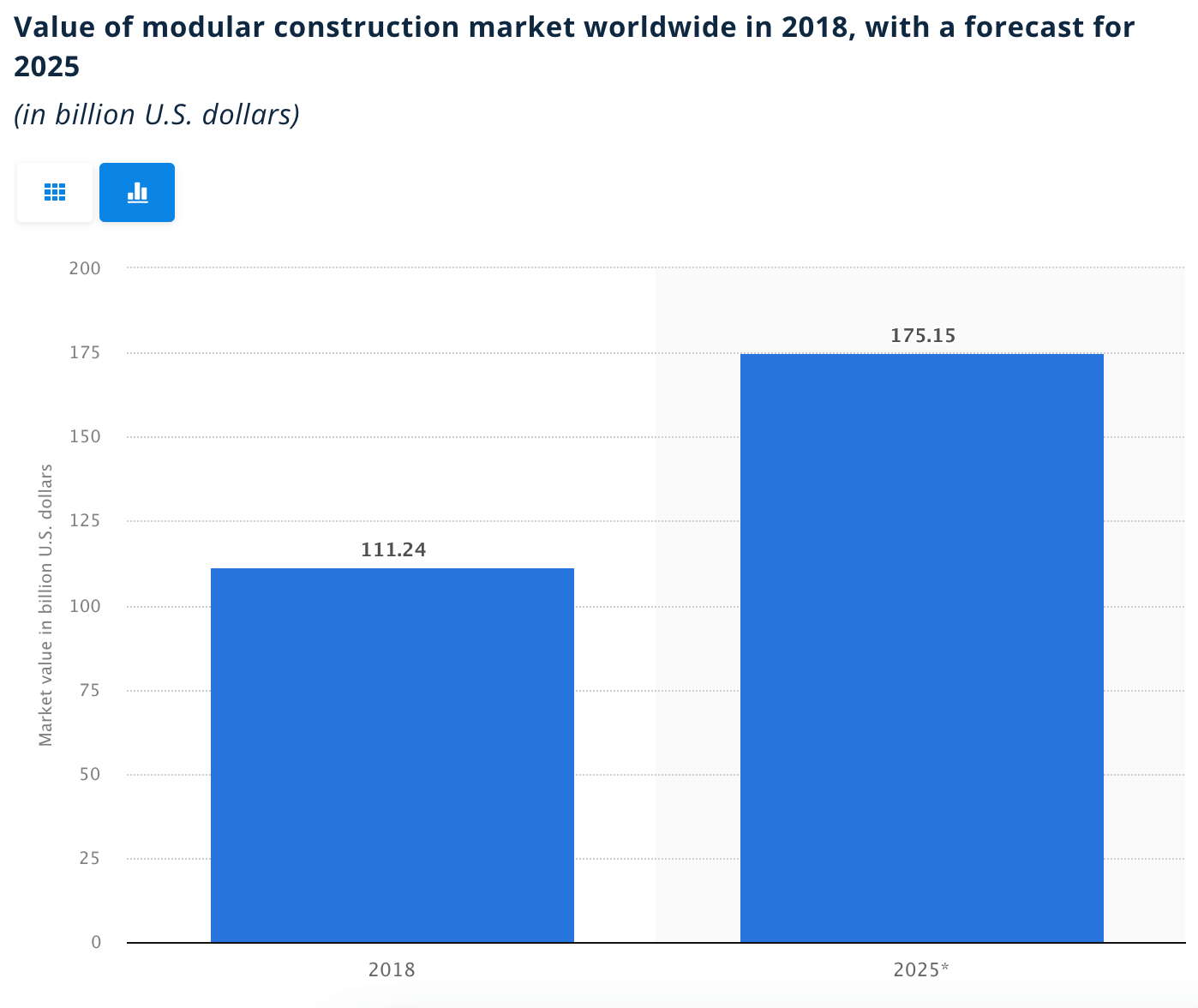

*Image from Statista

Modular Design and Prefabrication

Modular design and prefabrication have been gaining traction in the construction industry for years, and they’re only going to become increasingly popular in 2023. After all, by constructing building sections off-site and putting them together on-site, companies can shorten the construction process, keep costs low, and reduce waste. Contractors won’t have to worry about weather-related interruptions, teams can work on different tasks simultaneously, and there will be fewer transportation-related emissions and over-budget projects. It’s a win-win.

While the global modular construction market was worth $82.3 billion in 2020, it’s projected to grow to $108.8 billion by 2025, with some growth occurring in 2023. Everything from healthcare facilities to motels to apartment complexes can benefit from modular design and prefabrication.

*Image from Thiago Matos on Pexels.com

Fewer Workers

2021 saw the start of the Great Resignation, but people didn’t suddenly stop quitting their jobs in 2022. The construction industry struggled to find employees in 2022 and will continue to have difficulties recruiting workers (and, by extension, meeting project timelines) in 2023.

It’s worth noting that over 20% of construction workers are 55 years old or older, meaning they’ll likely retire in the next few years, leaving an even larger gap. Since it takes a while for knowledge to transfer from experienced workers to brand-new hires, finding and training young construction workers will be a top priority for many companies.

Unfortunately, many younger generations don’t view construction as a viable, rewarding career choice. There’s a major stigma attached to manual labor jobs, and the increased pressure on young adults to attend 4-year colleges has reinforced the idea that they need to aim for white-collar positions.

The good news is that companies are taking action to combat the worker shortage. For some, it means raising wages, offering retention bonuses, or heading into schools to spark students’ interest in the industry from a young age. For others, it means focusing on recruiting women. Everything from offering parental leave to creating recruitment campaigns that target women specifically can help bring them into the industry.

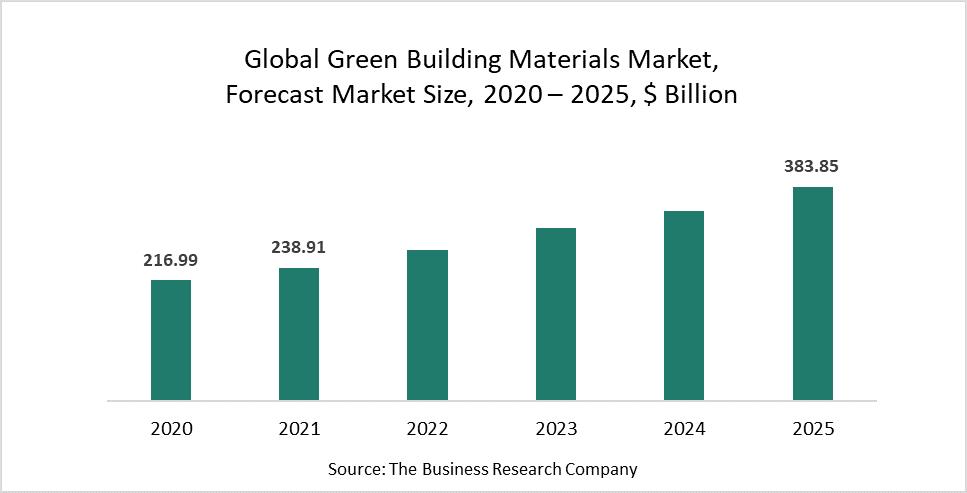

*Image from The Business Research Company

Green Building and Practices

Everyone is trying to go greener, and the construction industry is no exception. In fact, sustainability is one of the biggest construction industry trends in 2023.

When it comes to material selection, we can expect major changes. Living building materials like bacteria bricks and green roofs will become more popular in 2023 as people strive to become more environmentally friendly. Similarly, the use of traditional concrete may decline as people switch to new products like self-mending bio cement or self-replicating concrete. Companies may also choose locally sourced building products whenever possible to reduce transportation-related emissions.

The desire to become more sustainable also extends to the technology we use. More companies will abandon gasoline-powered engines in favor of electric-powered options. Not only are electric-powered loaders, excavators, and other power equipment greener than their gas-powered counterparts, but they’re also much quieter.

Material Shortages and Price Uncertainties

Material shortages are nothing new, and they’ll likely continue into 2023. Pre-ordering materials can help keep projects on track, though this will tie up your capital. Plus, ordering in advance means you’ll need to store all your materials somewhere and more time for something bad to happen to the materials. So, you’ll have to weigh your options carefully.

Material prices will also likely remain volatile. While the cost of lumber is slowly coming down, everything from aluminum to steel has experienced a price hike. Cement and concrete products will remain in relatively short supply, which, when combined with the high demand, likely means high prices. Combined with the high cost of diesel, the volatility of material prices will make accurately planning projects and staying within budget difficult.

More Technology

Technology is advancing quickly, and the construction industry is working hard to keep up. In 2023, expect more companies to adopt the latest technology. Not only will this technology enable them to work more efficiently, but it can even save them money in the long run.

For example, Building Information Modeling (BIM) is a popular tool that can help users create detailed, accurate virtual models of buildings. They can carefully study and completely conceptualize the project before even breaking ground. This allows contractors to identify and avoid potential problems in advance, saving everyone time, energy, and money.

Other tools to look out for include wearables, such as smartwatches, smart boots, smart glasses, and smart helmets. Not only will these technologies help keep the wearers safe on the job, but they’ll also give management a clear picture of exactly what’s happening on each site.

The popularity of drones will also continue to rise in 2023. With the help of drone technology, construction companies can become more efficient than ever. They can easily survey a project, view difficult-to-reach places, and gain a bird’s eye view of an entire site—all without putting anyone at risk. Thanks to drones, people can work from the office or even from home!

Construction robots can also help improve safety, while digitized workflows can boost productivity, drastically reduce paper waste, and allow people to work from anywhere.

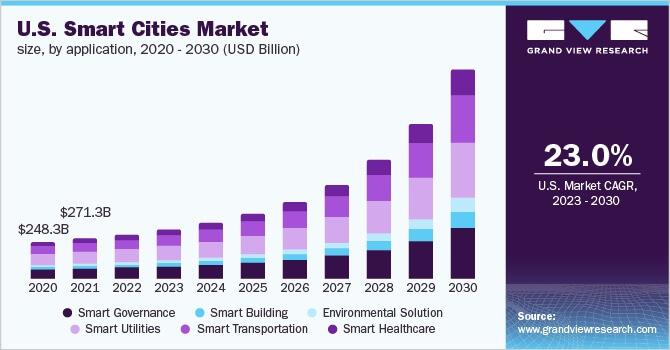

*Image from Grand View Research

Smart Cities

Smart cities, or cities integrated with Internet of Things (IoT) technology, are among the top construction industry trends—and with good reason. Compared to traditional cities, these cities offer reduced pollution, water waste, and traffic jams. The smart devices and sensors throughout the city will communicate this essential data, enabling people to make thoughtful, informed decisions to optimize their energy consumption and waste.

Smart cities will be greener than traditional cities and far more efficient, making life easier for everyone involved. So, it’s hardly surprising that the demand for smart cities will continue to rise in 2023. The global smart city market is expected to hit $2.5 trillion by 2025, and a large portion of that growth will occur in 2023.

Prepare for Success in 2023

2023 is shaping up to be an interesting year for the construction industry. Some building trends from 2022 will continue, such as the ongoing labor shortage, but new construction trends will also come to the forefront of the industry.

However, simply knowing what to expect in 2023 isn’t enough to guarantee success. You’ll also need to take action and do everything possible to make your business profitable. As a contractor, that means saving time and money wherever possible. As a supplier, that means selling your products at the price you deserve.

That’s where AMAST comes in. AMAST’s B2B online marketplace connects contractors to quality materials from suppliers, and suppliers to verified customers. It’s convenient and reliable, making it a win-win for everyone.